Feb 13, 2025

Cell to system explained

At Ceres, we’re at the forefront of clean energy with our innovative metal-supported solid oxide technology; When it comes to solid oxide, it is all about structure, structure, structure – Ceres. World-leading cells are the foundation of our technology.

To get to meaningful amounts of power (SOFC) or hydrogen production (SOEC), many cells are assembled on top of each other vertically into modular building blocks based on output called stacks. Unlike other solid oxide stacks which rely on the use of glass seals to seal these cells together, Ceres’ metal supported cell use commercially available gaskets, leading to stacks that are fundamentally more robust and durable in handling, transport and most importantly, operation.

The stacks are installed into systems based on application. Due to the reversible nature of Ceres’ highly efficient cell technology, it can run in two operation modes:

- Run in one way you can generate power for use in applications such as data centres.

- Run in reverse you can run in electrolysis mode to produce green hydrogen.

This means that one factory can manufacture cells and stacks for both power generation and electrolysis, resulting in a product portfolio for a myriad of current and future applications.

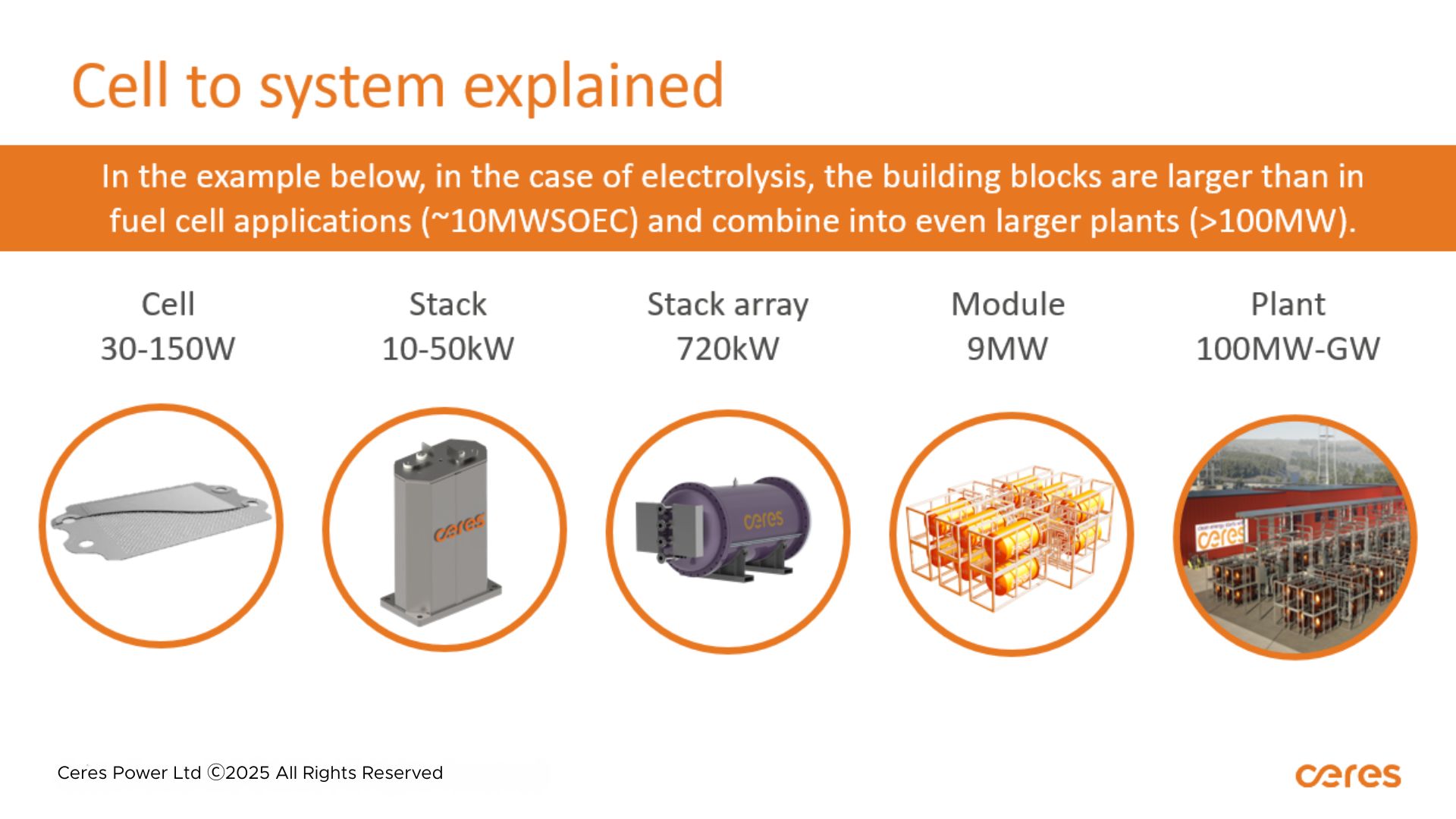

These stacks are then assembled into larger building blocks (arrays of stacks) and then systems for higher power applications. In the case of electrolysis, the building blocks are larger than in fuel cell applications (~10 MWSOEC) and combine into even larger plants (>100 MW).

The low operating temperature of Ceres’ cells means that lower cost materials and commodity steels and seals can be used in the supporting equipment such as heat exchangers, blowers and piping.

Ceres’ lower operating temperature has further benefits at industrial plant level. Compared to solid oxide electrolysers operating at higher temperatures, heat loss from pipes and pieces of equipment in Ceres’ system is minimal. It means that things like heat exchangers can be centralised, further decreasing capital costs.

While Ceres specialises in the cell and system technology, we work closely with EPCs like Atkins Realis to provide a concept framework and foundation of application-specific plant-level design.