Feb 25, 2025

When it comes to solid oxide, it is all about structure, structure, structure

In previous blogs we’ve introduced solid oxide technology broadly: Solid oxide technology: Powering the net-zero future – Ceres and highlighted its ability to operate across a wide temperature range: The goldilocks zone: how Ceres has optimised solid oxide – Ceres. The reason for the large differences in temperature (450-1000°C) is that there are three distinct types of solid oxide cells.

The three types of solid oxide cells are differentiated by what provides the mechanical stability for the cell. This crucial point dictates everything – the operating temperature, ease of manufacture, robustness, reliance on exotic materials and cost.

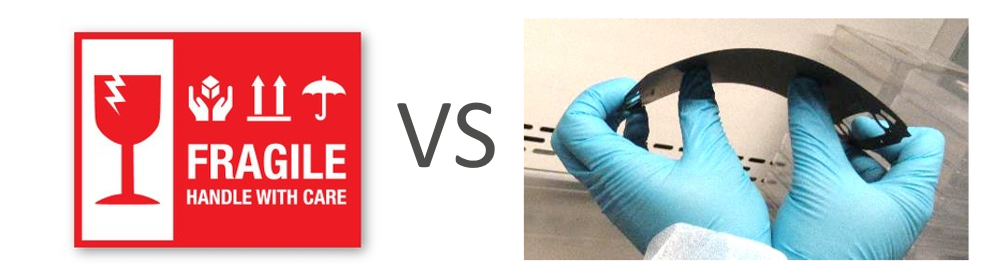

- Fuel-electrode supported: These cells resemble very lopsided sandwiches, with the porous (nickel) metal + ceramic fuel-side layer being ~10 to 25 times thicker than the other porous layer, requiring large amounts of expensive ceramic materials. They operate at 700-850°C and must rely on glass seals applied in a challenging step at the end of the production line. The seals are extremely fragile, requiring very careful handling, transport and operation of the stack.

- Electrolyte-supported: In these cells, the dense filling layer is the thickest, requiring even higher operating temperatures (800-1000°C) to overcome resistance. Exotic materials are needed to withstand these temperatures. Manufacturing is more difficult, as it requires even higher temperatures to make that layer gastight and fragile glass seals are still required, reducing robustness, increasing cost and nearly eliminating the ability to thermally cycle.

- Metal-supported: These cells are like very thin ceramic sandwiches served on a low-cost, perforated stainless-steel plate. The ceria-based electrolyte (Three reasons why Ceria is a low-risk choice for SOEC stack manufacturing – Ceres) used by Ceres enables lower operating temperatures (450-630°C) and is easier to densify. The cost-effective metal support enables robust, laser welded seals like those already used in cars, planes and electronics, making these cells ideal for mass manufacture.

It is clear that cell structure directly impacts not only performance and robustness but also manufacturability and cost. By pioneering metal-supported SOCs, Ceres is working with our partners to bring the most cost-effective, durable, and scalable solutions to market, making it easier to integrate clean energy into a wide range of industries and applications.