Explore our product families

Our family of market leading solid oxide products, incorporating our unique low-cost metal supported technology, enable our licensee partners to enter growing markets with confidence and pace.

Explore these products and the market opportunities.

Products

Ceres’ products offer its partners packages of innovation, designs, expertise and intellectual property rights.

Applications

Ceres provides industrial, commercial and marine power solutions, as well as hydrogen applications for green ammonia and refineries.

Blueprint

Core products

Cell

Stack

Factory

System products

Power

Power Module

Power System

Hydrogen

Stack Array Module

Electrolyser Module

Applications

Data centres

Commercial Power

Industrial Power

Marine

Ammonia

Refineries

Green Steel

eFuels

Core Products

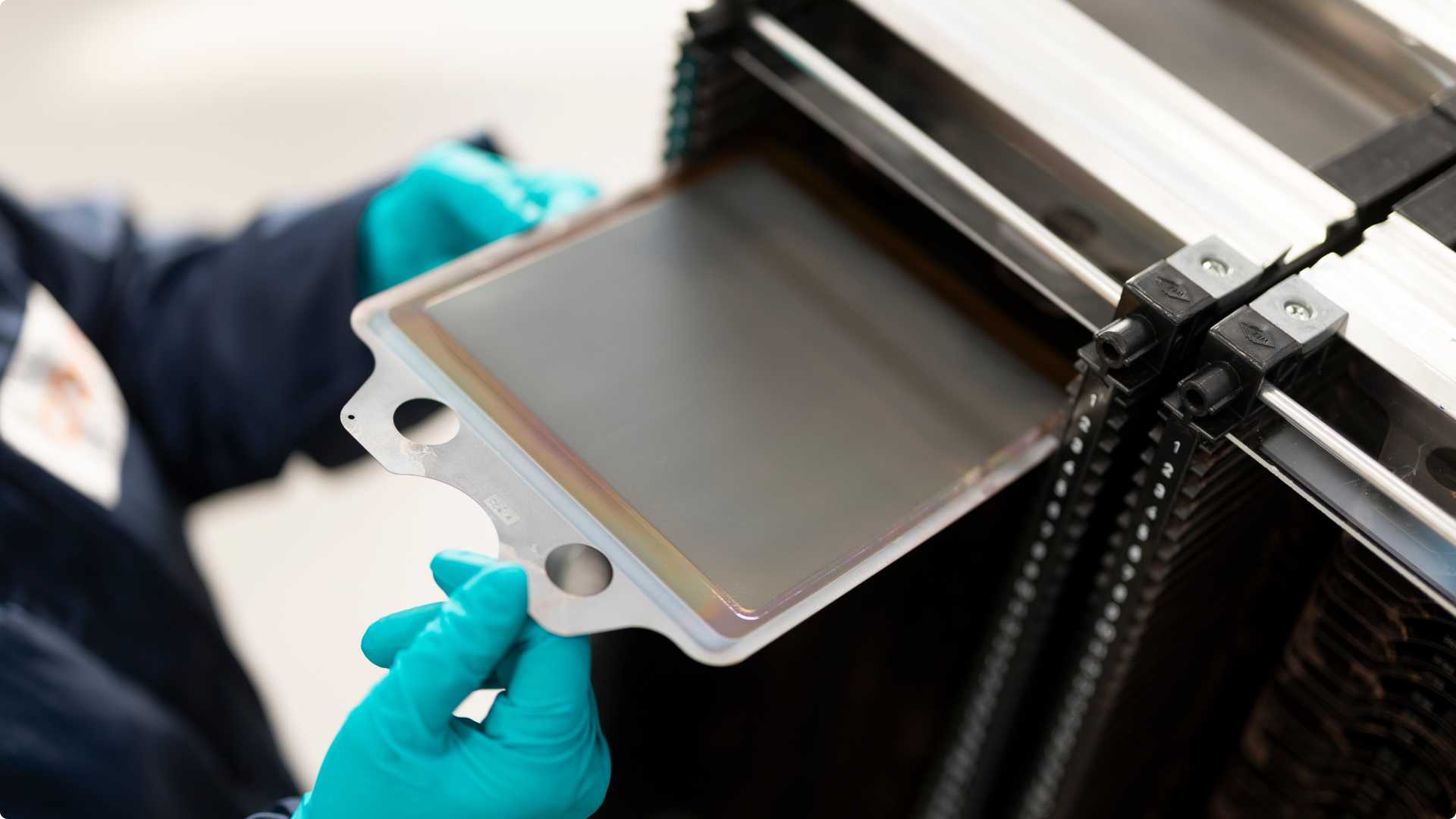

Cell

Stack

Factory

Cell

Stack

Factory

System Products

Power

Power Module

Power System

Hydrogen

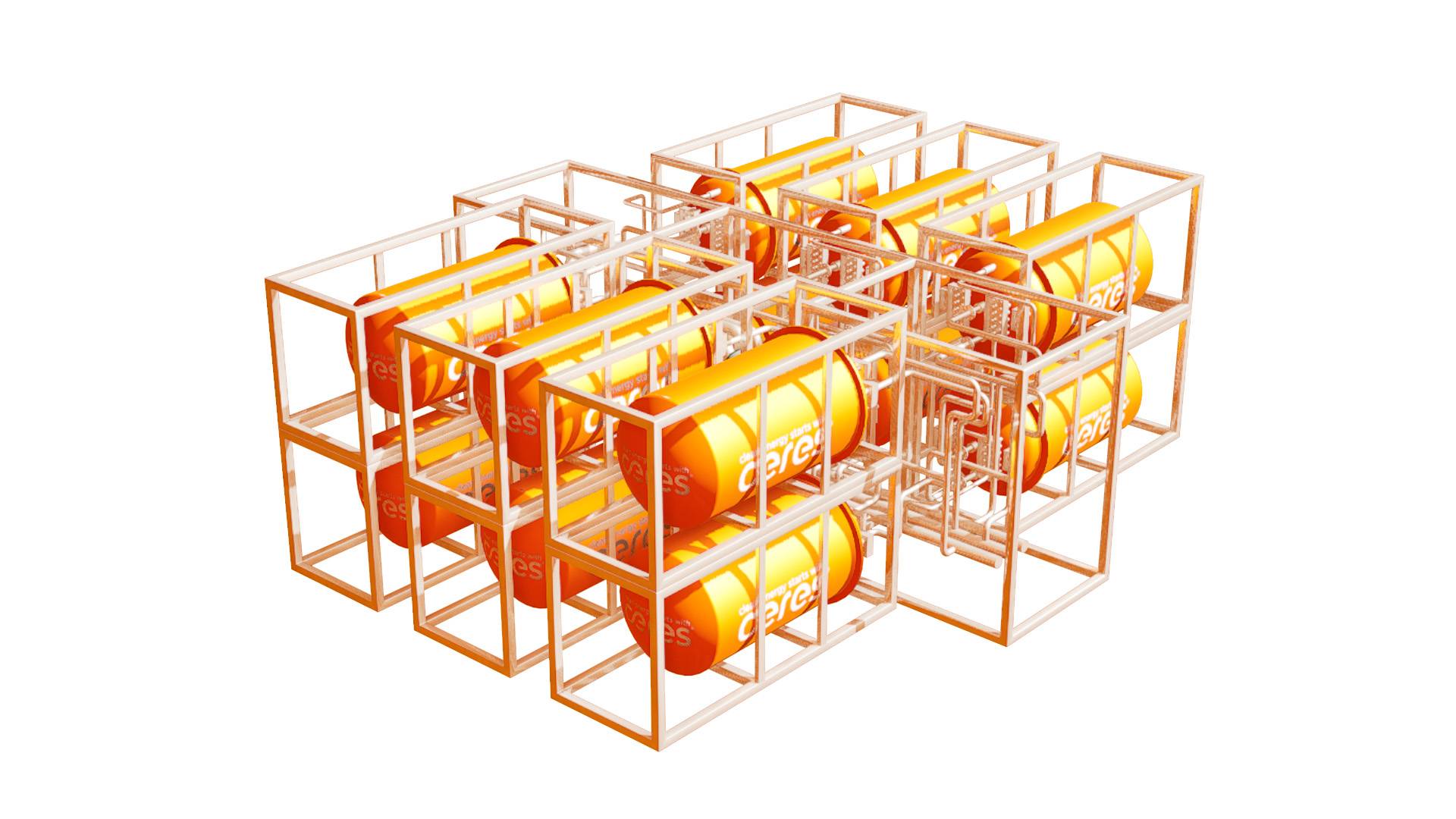

Stack Array Module

Electrolyser Module

System Product - Power

Power Module

Power System

Applications - Power

Data centres

Commercial Power

Industrial Power

Marine

System Product - Hydrogen

Stack Array Module

Electrolyser Module

Applications - Hydrogen

Ammonia

Refineries

Green Steel

eFuels

Speak to our experts

Contact us: marketing@cerespower.com

Find out more

Products

Ceres’ products offer its partners packages of innovation, designs, expertise and intellectual property rights.

Applications

Ceres provides industrial, commercial and marine power solutions, as well as hydrogen applications for green ammonia and refineries.

Blueprint

System products

Power

Hydrogen

Applications

Speak to our experts

Contact us: marketing@cerespower.com

Find out more

Products

Ceres’ products offer its partners packages of innovation, designs, expertise and intellectual property rights.

Applications

Ceres provides industrial, commercial and marine power solutions, as well as hydrogen applications for green ammonia and refineries.